Cannabis and Humidity: Challenges and How To Overcome Them

Cannabis and humidity do not get along. Moisture is one of the biggest downfalls of any size grow, from small craft farms to large-scale operations, but it’s also an unavoidable part of the experience. Fresh cannabis typically clocks in at around 75 percent moisture, but it’s a double-edged sword: a humidity problem or flower with too-high moisture content can easily tank product quality, leaving you with subpar flower and even a completely unusable crop. As a commercial cannabis or hemp grower, what can you do to better control humidity and your flower’s moisture content?

Humidity and moisture: What problems do they cause?

There are two main ways humidity comes into play in a commercial cannabis grow: the environment in which the cannabis or hemp is grown, and the moisture content of the plant material itself. If your grow room is too wet or humid or the plant material itself is too wet, your cannabis or hemp flower is at risk for developing harmful mold and mildew. These contaminants are easy to develop, and once they take hold, they are nearly impossible to remove.

Flower contaminated with mold cannot be smoked. It is important to note, however, that trace amounts of mold and mildew are not necessarily harmful and flower can pass lab tests showing what’s considered “acceptable” amounts by the requirements outlined by a particular regulatory body. However, medical cannabis patients need to be particularly careful, as they may be particularly susceptible or sensitive to mold.

Cannabis grows with too high humidity or moisture can also exhibit signs of a condition called “bud rot.” Bud rot is a type of fungus called botrytis cinerea that develops inside flower early on and appears closer to the harvesting stage. This highly contagious fungus spreads easily throughout the entire plant and can quickly leap to other plants.

A key way to keep these harmful growths at bay is to tightly control wetness, humidity, and moisture conditions during the growing, cannabis drying, and cannabis curing process. But there is such a thing as cannabis that’s too dry. Too little humidity or moisture content can make smokable cannabis and hemp flower brittle, where it crumbles in your hand instead of grinding up nicely. There is a common misconception that cannabis can be “rehydrated,” but this process can damage trichomes and subsequently plummet the cannabinoid content of your flower. Notably, though, extractors benefit from ultra-low flower moisture levels, as this results in higher cannabinoid and terpene yields.

What’s the ideal moisture content for cannabis and hemp flower?

If both too wet and too dry conditions have undesirable results for smokable cannabis and hemp flower, is there such as thing as ideal moisture and humidity levels?

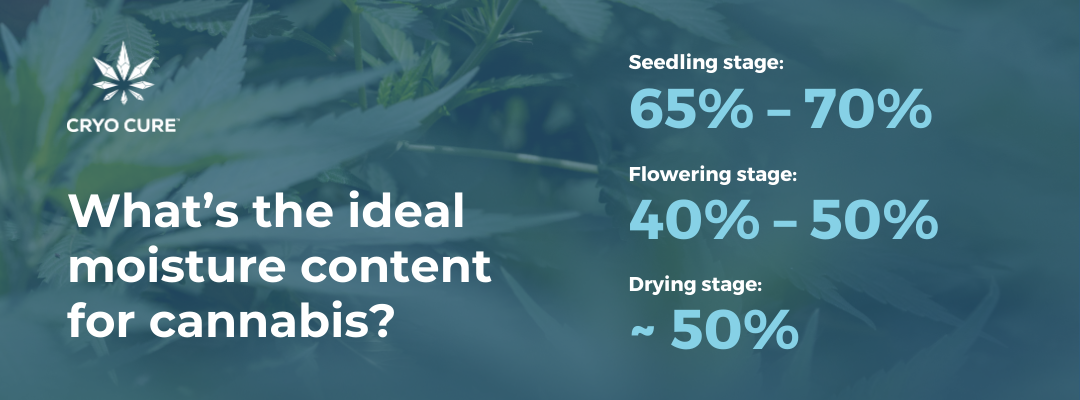

When it comes to controlling the growing environment, humidity needs vary depending on the growth stage. The humidity level in the grow facility changes depending on whether your crop is at the seedling stage, vegetation stage, or flowering stage. A humidity level between 65 percent and 70 percent is recommended for the seedling stage, while this figure should be lowered during vegetation. Generally, the flowering period can thrive in humidity levels between 40 percent and 50 percent. Some may choose to lower humidity once more during the last flowering stage.

During the critical cannabis drying stage, moisture content is brought down from the plant’s natural levels. As the cannabis dries, the moisture comes off the plants and lingers in the air, making managing humidity in the drying room of utmost importance. Generally, growers try to keep humidity levels at around 50 percent in the drying room.

As for the moisture content of the flower itself, cannabis growers typically strive for no more than 15 percent moisture content once the cannabis drying and curing process is complete. Cryo Cure’s patented cannabis drying and curing processes stabilize flower at between 8 percent and 12 percent moisture content– just enough to keep it fresh while lowering the chances that mold, mildew, and fungus thrive.

What other environmental factors impact cannabis quality?

While humidity and moisture content are significant issues for cannabis growers, this is far from the only factor that needs to be monitored and carefully controlled. Temperature, air, and light also play a role in cultivating, drying, and curing quality cannabis that does not suffer from issues with quality like moisture-driven problems and THC degradation.

- Temperature: Not only do too-warm temperatures kickstart decarboxylation and boil off precious cannabinoids and terpenes, but they impact humidity, too. Moisture has the chance to thrive when coupled with higher temperatures.

- Air: Exposure to oxygen drives the degradation of THC and other cannabinoids and terpenes, resulting in a less potent consumption experience. Circulation and ventilation in the growing and drying environment are also of vital importance, as they help mitigate humidity and control moisture levels.

- UV rays: Dark rooms and containers are best during the cannabis drying and curing process. Exposure to UV rays accelerates the breakdown of all organic matter, cannabis included, and this decay can contribute to fungus growth.

How Cryo Cure helps you control moisture levels

As we established in this blog, humidity and moisture content are crucial to a successful cannabis harvest. Cryo Cure is an important tool to help you mitigate these factors before they become a problem in your cannabis or industrial hemp growing facility.

Cryo Cure’s patented technology preserves that “fresh from the farm” feeling without any of the moisture levels prevalent in live plants. By freeze drying wet cannabis, THC levels are stabilized as the cannabinoid and terpene-rich trichomes are perfectly preserved in a way that no other cannabis drying or curing process can achieve.

By skipping the hanging phase of drying, Cryo Cure mitigates one of the most volatile variables in the cannabis drying and curing process: time. Not only does this get your products onto the shelf faster, but shortening the window can help you avoid many of the problems triggered by prolonged exposure to the elements, including moisture-related bud rot and mildew growth.

Our machines are tuned to preserve between 8 percent and 12 percent of your flower’s moisture content, but you can customize the settings for strain-specific outcomes or any other desired end. This includes extraction specific settings that can bring down moisture content as low as 1 percent, preferred for maximum cannabinoid and terpene yield.

As you plan out your cannabis or industrial hemp grow operation or explore ways to upgrade your facilities, keep humidity and moisture content control central to your strategy. View the Cryo Cure models page to review your options, and contact Cryo Cure to discuss how to bring our machines to your facility.