The Ins and Outs of Terpene Extraction

Terpene extraction has long taken a back seat to fine-tuning phytocannabinoid levels and flower quality during the cultivation process. That’s because harvesting and collecting terpenes is a herculean task for many growers, taking lots of work for seemingly little yield, especially if the flower is destined for phytocannabinoid extraction. However, as the interest in terpenes grows, so does a cultivator’s opportunity to invest in terpene extraction as another revenue stream. What are your options for maximizing terpene extraction opportunities in your next harvest?

What are terpenes, and why are they so difficult to extract?

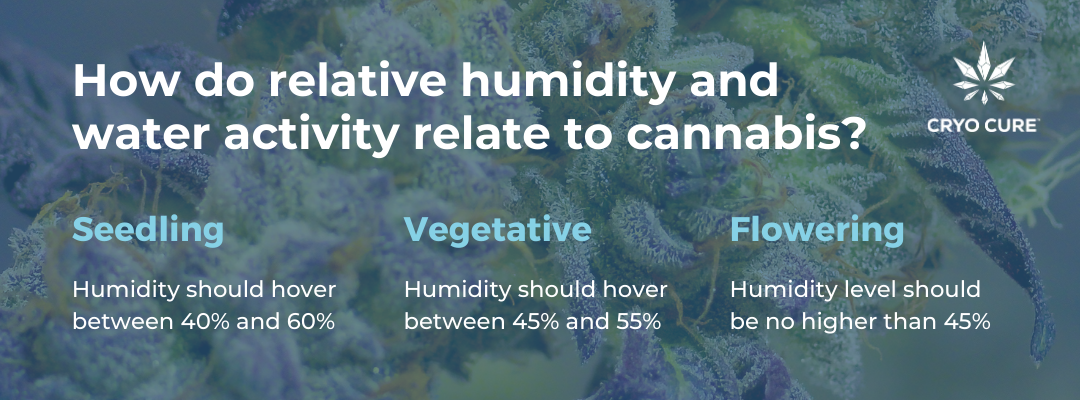

From fruity and sweet, funky and earthy, and every variation in between, that tell-tale cannabis aroma is the result of a naturally occurring substance secreted by the plant called terpenes. Terpenes are a compound that not only hits your sense of smell, but can also greatly affect the taste of cannabis.

Since their discovery in the late 1800s, scientists have identified more than 20,000 terpenes in species of plants across the globe. When you narrow the scope to just cannabis, scientists estimate that there may be up to 200 terpenes.

Research into individual terpenes has found they have a dizzying array of incredible properties, including pain relieving, anti-anxiety, and stress-busting effects, all of which contribute to how cannabis makes you feel. Terpenes play a major role in whether a cultivar (strain) will sedate or energize you – not whether the plant’s phenotype is classified as a sativa or an indica, a common cannabis myth. Additionally, terpenes are theorized to work together with phytocannabinoids like Tetrahydrocannabinol (THC) and Cannabidiol (CBD) to create what’s commonly referred to as the “entourage effect.” All in all – a very valuable compound!

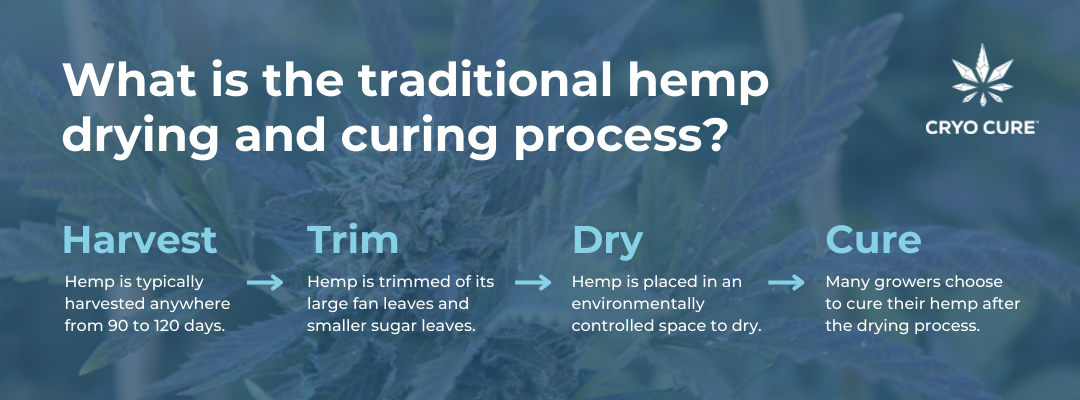

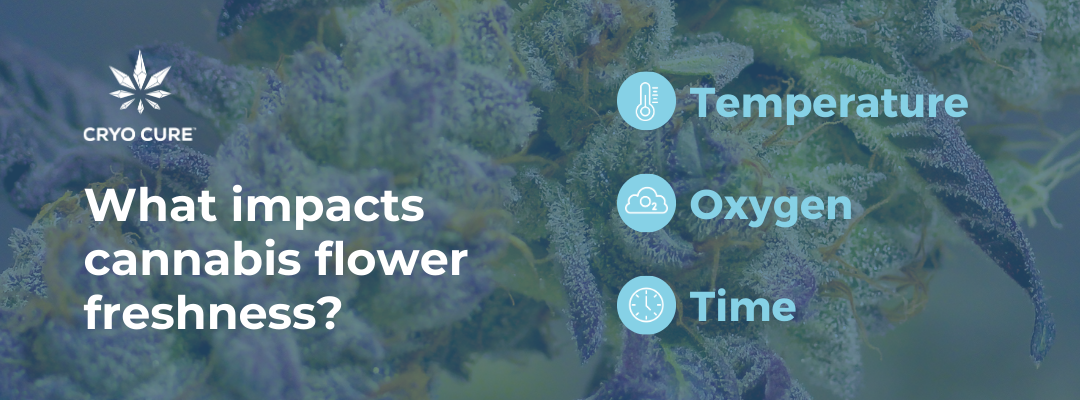

But here’s the catch: harvesting these terpenes is not an easy feat. If you’ve ever walked through a grow room and immediately noticed the smell, you’re actually experiencing those terpenes evaporating off the plant. That’s because as short-chain hydrocarbons, terpenes are susceptible to a quick evaporation rate, particularly at warmer temperatures. Terpene loss begins the moment the plant is harvested, so preserving these precious compounds becomes a race against the clock.

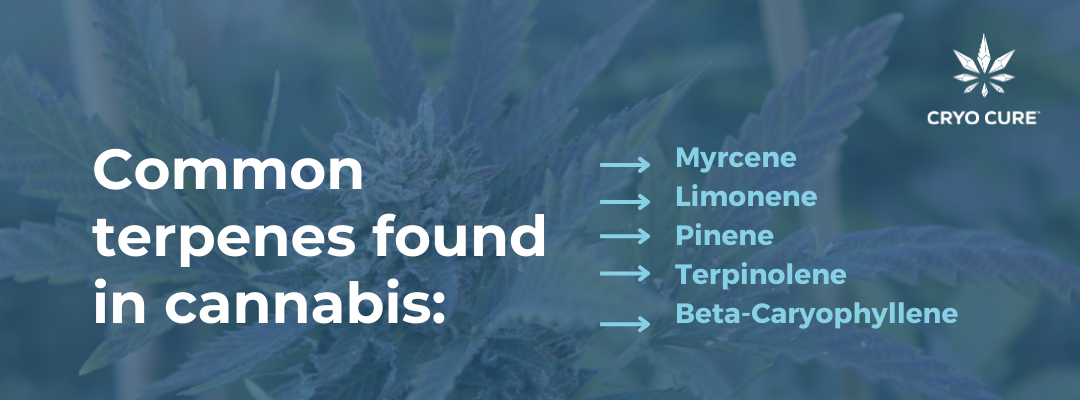

Common terpenes found in cannabis

Though numerous terpenes occur naturally on cannabis, some are more prevalent than others. The following six terpenes are high in concentration among the various strains of cannabis and are easily recognizable once you know what to look for.

- Myrcene: Considered possibly the most common cannabis terpene, myrcene is why cannabis often has an early, musky smell associated with it. Myrcene is known as a relaxing agent and has anti-inflammatory properties. It’s commonly found in cultivars with indica lineage, which may be why “indica strains” are associated with sedation and relaxation.

- Limonene: Cannabis flowers with a citrusy smell are often high in limonene, which makes sense since it’s also predominantly found in citrus fruits. This compound is commonly used in household and cosmetic products, but in cannabis it’s known to help reduce stress and improve mood. It’s also been found to improve the permeability of topical products.

- Pinene: You can find pinene in two variants: alpha pinene and beta pinene. Alpha pinene is more prevalent in cannabis than its cousin. Also commonly found in pine trees, rosemary, and parsley, the pinene terpenes have an anti-inflammatory effect, and may be a bronchodilator, or may open up the airways.

- Terpinolene: This terpene can sometimes smell a little citrusy and a little like a bouquet of flowers, while also tasting like mint or anise. As a terpene found in cannabis, terpinolene has relaxing properties and is commonly behind the “couch lock” effect that some cultivars and the phytocannabinoid Cannabinol (CBN) may cause.

- Beta-Caryophyllene: If you’ve ever experienced cannabis with a spicy smell and a hint of black pepper, then you’ve experienced this terpene in action. Commonly found in black pepper, cinnamon, and cloves, beta-caryophyllene is the only terpene we know of so far that binds to cannabinoid receptors like its phytocannabinoid and endocannabinoid counterparts. This terpene is an analgesic and can help stave off anxiety.

How are terpenes extracted from cannabis and hemp?

In recent years, terpene extraction has been a hot topic in the cannabis industry. There have been two main ways in the past that cannabis cultivators sought to extract terpenes from their crops: hydrodistillation or steam distillation.

Hydrodistillation occurs when you boil the plant in a solvent like ethanol, butane, nitrogen or CO2. One example of this method is when you take CO2, which is a gas, and heat it up in a pressurized environment. The gas is turned into a liquid, which is then run through the plant. The resulting liquid that comes from the process is then dried and the terpenes are extracted from the final product. Doing it this way can ensure you get the full or broad spectrum of all compounds found in the plant, including terpenes.

Steam distillation takes place when you boil water in a vessel under a hanging basket of cannabis. As the water evaporates and steam escapes the vessel, it passes through the cannabis, capturing the lighter oils before it’s collected in a condensation flask. Once the liquid is cooled, the oils and terpenes can then be more easily extracted.

Terpene harvesting pitfalls and challenges

One of the hardest aspects of terpene harvesting is how fleeting the substance truly is. As a short-chain hydrocarbon, terpenes evaporate very easily and from the moment cannabis is harvested. This makes proper extraction difficult and historically not worth the effort for growers.

Even harder is the extraction of monoterpenes. These compounds boil off during traditional curing methods. One of these monoterpenes that was recently found is carene, which is believed to be found in all cannabis. Known to have a sweet and citrusy smell, carene is known for its anti-inflammatory and bone-strengthening properties. Unfortunately, it boils off during the hang drying process, so the average consumer never gets to experience it for themselves. (Unless they’re trying Cryo Cure, which has tested positive for carene and several other monoterpenes!)

Because terpenes are so incredibly fragile, the extraction process can be hard on them. Many terpenes easily break down altogether, making their extraction an even harder prospect. Some monoterpenes are so light that they will boil off no matter what you try to do in most traditional methods. Furthermore, solvent-based methods of terpene extraction run the risk of contamination. For example, ethanol destroys terpenes, leading to a very small yield.

Even if your extraction methods are sound, the process often yields a small amount of terpenes since the terpene profile diminishes as time goes by. Terpenes begin to evaporate from the moment you harvest your cannabis or hemp. As such, it’s incredibly difficult to extract terpenes and sell them on a large enough scale.

The Cryo Cure approach to cannabis terpene extraction

Here at Cryo Cure, we pride ourselves in the fact that our machines can consistently extract terpenes. We utilize three approaches to cannabis terpene extraction: live resin extraction, terpene “recapture,” and the direct stripping of terpenes for extraction.

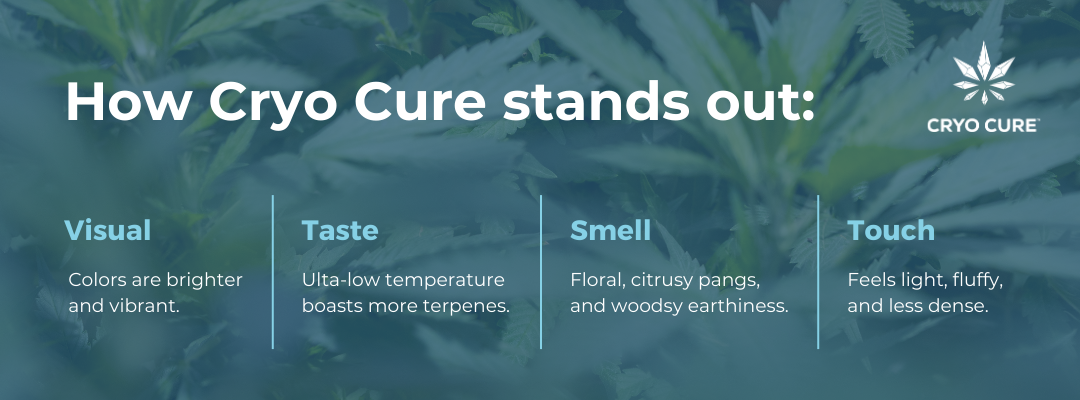

- Live resin extraction: Through our patent pending process, our machines stabilize the phytocannabinoid and terpene content of cannabis. This happens early in the drying and curing process, capturing terpenes at a higher level before they can evaporate and degrade. It’s through this method that we can capture the ultra-rare terpenes and monoterpenes that you don’t get from the more traditional dried and cured product – not to mention higher yields of common terpenes. What you get from this method is smokable flower that’s significantly higher in terpene concentration than other products.

- Recapturing terpenes: Our Cryo Cure machines have an ice bank that gathers terpenes typically lost during the drying and curing process. By capturing vapor and recondensing it into the ice bank, we can collect and melt down the terpene-rich water removed from cannabis during our process. Once melted, we put the water into a centrifuge, which allows us to remove 95 percent of the once lost terpenes. This results in a collection that can go for $50 to $100 per milliliter. For every three acres of hemp or cannabis you cultivate, that means you could potentially harvest enough terpenes worth $2 million at retail! It’s a great way of taking your crop and adding another revenue stream to it without depleting the quality of the flower.

Terpene extraction with Cryo Cure: Don’t leave valuable compounds behind!

Though there are multiple ways to pull terpenes out of your crop, few are as efficient as Cryo Cure. Our machines not only cut the drying to as little as 11 hours, but it can add an entirely new revenue source for your crop with its terpene extraction settings. By preserving the fragile trichomes that house the plant’s phytocannabinoids and terpenes, our machines help you provide your customers with the freshest tasting and smelling cannabis they’ve experienced. If you want to Cryo Cure your crop and make your operation a more modern one, contact Cryo Cure today!