Greg’s Guide to Curing Cannabis: Learn From Cryo Cure’s President and Head of Cultivation

You can’t skip the process of cannabis curing, but conventional methods are time consuming and, if performed incorrectly, could result in the growth of mold and mildew. Fortunately, modern approaches and smart solutions have improved the curing process, saving cultivators time and money while reducing the risk of cultivation.

In this guide, Greg Baughman, President and Head of Cultivation for Cryo Cure, talks about the importance of curing, how it’s been done historically, and the more efficient approach now available to cultivators everywhere.

What does curing cannabis do?

Curing cannabis balances the moisture content across all buds following the drying process and serves to prevent the growth of anaerobic bacteria, as well as the degradation of important compounds. Curing is necessary because smaller buds dry out a lot faster than bigger buds during drying. Curing causes the smaller, dried-out buds to absorb excess moisture from the bigger buds, resulting in finely preserved cannabis that is crisp, ready-to-smoke, and protected from contaminants like mold and mildew.

How has harvesting, drying, and curing been done historically?

There is no one standardized way to harvest, dry, and cure cannabis. Many cultivators use processes they developed themselves, so it’s common to see differing methods from grower to grower.

Common methods of curing cannabis include curing in jars, wet curing, heat curing. However, each of these have limitations. Improperly curing in jars could actually promote the development of mold and mildew, and it limits how much cannabis can be cured at scale. Wet curing cannabis removes terpenes, reducing the flavors, aromas, and effects associated with those compounds. And heat dehydration curing can cause degradation of cannabinoids and terpenes, resulting in a lower quality final product.

To limit these downsides, Greg developed his own drying and curing method while serving as a caregiver in Michigan’s medical cannabis program, before he designed the Cryo Cure machines.

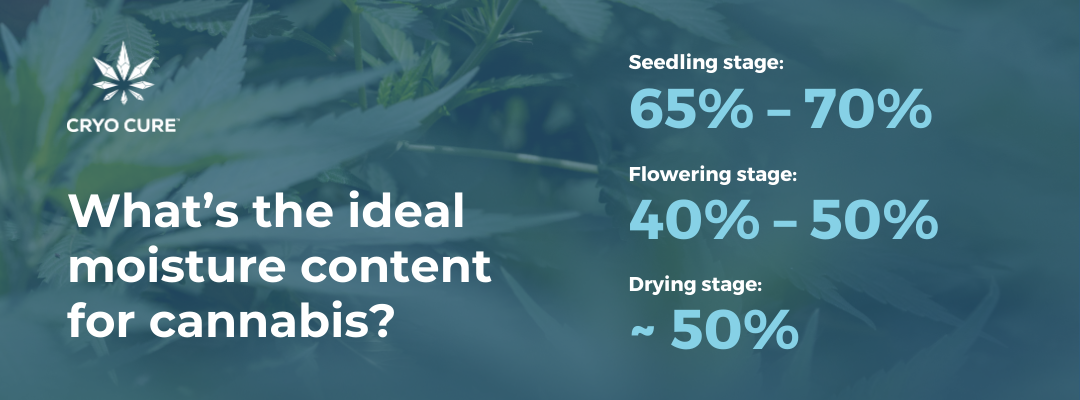

“I would cut the plants down whole and hang them in a dark room, where I’d keep the temperature at 65℉,” Greg said. “I would keep it at 55% humidity for the first four days, and 40% humidity for the last three days.”

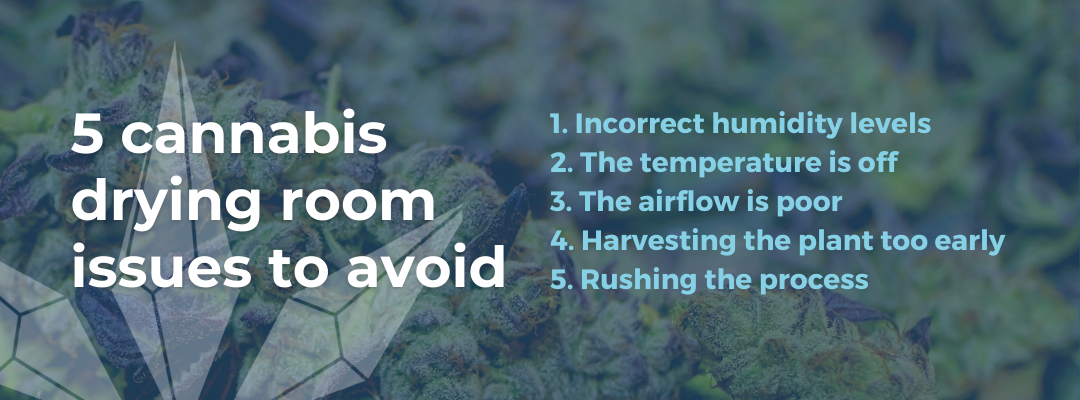

In addition to setting the right temperature and humidity levels, the drying room needs sufficient airflow to keep the room cool. Because hot air rises, Greg would run an air conditioner from the ceiling to keep temperatures at acceptable levels throughout.

After a week, Greg said he would take the plants down and hand trim them before curing. To cure the flower, Greg would place the trimmed buds in airtight turkey bags – the same ones used to cook a turkey in the oven. He would then leave the buds to sit overnight. At this point, the smaller, dried-out buds would absorb moisture from larger buds.

“Because it’s an airtight container, moisture seeks its own level. If there are smaller buds, that moisture is going to be absorbed from the bigger buds and essentially equal out the product,” explained Greg.

The goal of curing, he added, is to reach 8% to 12% moisture content and 0.5% to 0.6% water activity (aW) in each bud — any higher risks the development of anaerobic bacteria like mold. Generally, Greg could tell the curing process is complete by feeling the buds. If the buds were crispy, he said, they were ready; if not, he would reseal them in the turkey bags for a few hours before checking again.

How long does curing cannabis take?

Traditional methods of drying and curing could take anywhere between 10 and 30 days to be completed. That represents a significant loss in potential revenue for commercial cultivators who are growing at scale — a capital-intensive operation — and want to sell their flower as soon after harvest as possible to support their cash flow. While the curing process itself can be done as quickly as one day using Greg’s method, it can’t be done until the flower is properly dried. With Greg’s pre-Cryo Cure method, drying takes a week, but can take even longer depending on the process other cultivators use – some cultivators dry their flower for two weeks or more.

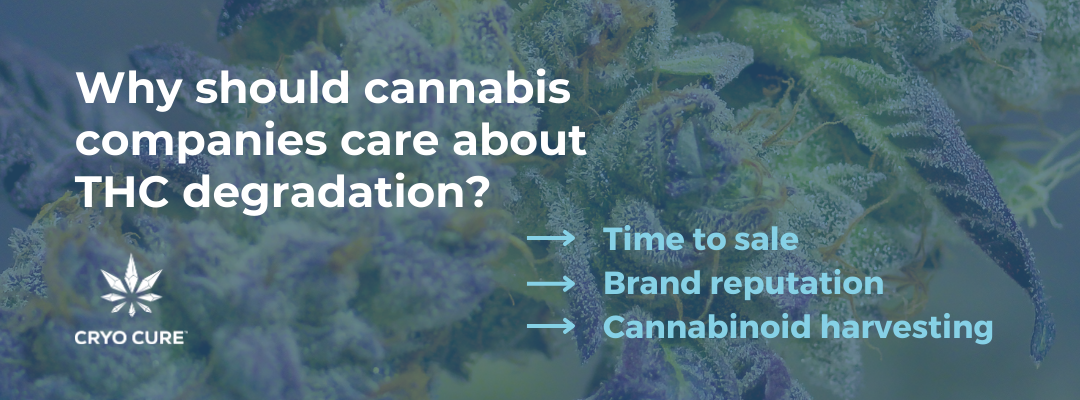

The challenge with lengthy drying periods is that each day cannabis spends drying represents lost potential revenue for a cultivator. In addition, cannabis flower left to dry and cure for more than a week loses significant amounts of terpenes because terpenes degrade naturally over time. This timeline accelerates when cannabis is exposed to oxygen, heat, humidity, and light. Lower terpene content means less product appeal on dispensary shelves, so preserving terpene content after harvest is especially important.

Thankfully, equipment like Cryo Cure’s is changing the game and speeding up the time required from harvest to sale.

How Cryo Cure expedites drying and curing cannabis

Cryo Cure simplifies and shortens the traditional drying and curing process by dialing in the precise ratio of time, temperature, and pressure to achieve the perfect moisture levels in the flower. This process can be completed in seven steps that only take one day to complete.

- Chop down cannabis plants.

- Defoliate the plants and cut to packageable size.

- Arrange the buds on baking sheets to be loaded onto carts.

- Place the carts in a -20℉ walk-in freezer for a minimum of 2 hours.

- Transfer the carts into a Cryo Cure machine for 12 to 16 hours to dry (rather than a week or more in a drying room).

- Remove the buds from the machine for trimming and manicuring.

- Place buds into an airtight chamber to cure overnight.

Using a Cryo Cure vacuum chamber allows cultivators to eliminate the traditional hang drying process, reducing the time frame from up to a month to less than 24 hours. In many cases, the runtime can be reduced to as short as 12 hours. The process results in several benefits to product quality, including:

- Bigger buds – no shrinkage

- Vibrant appearance

- Stellar terpene retention

- THC-A stabilization – no degradation into CBN

Curing cannabis is critical to preserving flower quality for the long haul, but until now it was a labor intensive and lengthy process. Luckily, with Cryo Cure, curing cannabis is now easier and faster than it’s ever been..

Curing cannabis with confidence

There will always be debate regarding the best process for drying and curing cannabis. While many people think that slow and low is the way to go for cannabis, Cryo Cure has developed a process to achieve the same results much more quickly and efficiently. In a cannabis industry where time is money and quality is on every consumer’s mind, the Cryo Cure method offers a better way to get your flower market-ready. Visit our website or speak with one of our experts today for more information on our patented technology and methodology.