Cannabis extraction makes it possible to create new and innovative products, but it’s a process that has remained relatively unchanged for decades. As the cannabis industry expands across the U.S. and the globe, however, emerging technologies are simplifying the process, preserving sensitive terpene content, and capturing more overall phytocannabinoid content.

How are these innovations changing how the cannabis industry makes concentrates, edibles, vape cartridges, topicals, and other products? Here are some cannabis extraction technologies you should know about – and how Cryo Cure is contributing to the conversation.

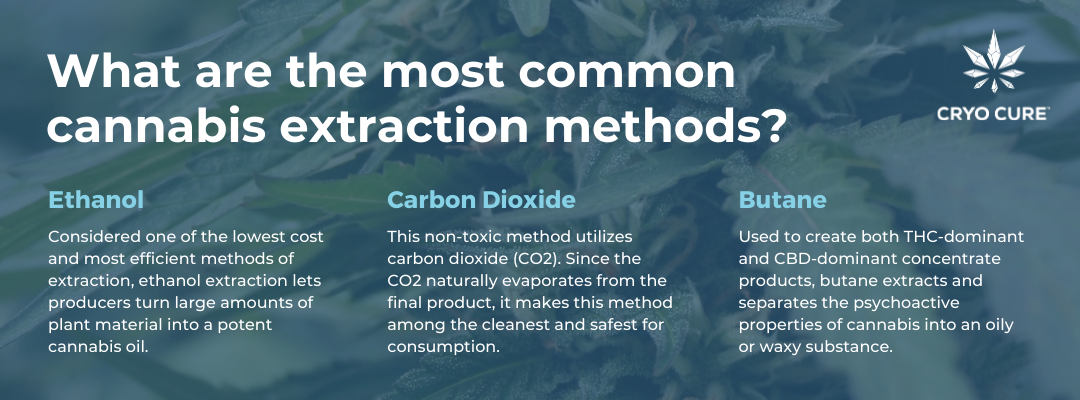

What are the most common cannabis extraction methods?

The goal of cannabis extraction is to pull out the more desirable compounds in the flower and use them in other products. With cannabis, manufacturers are most interested in phytocannabinoids (both major ones like THC and CBD, and minor cannabinoids like CBC and THC-V) and the fragile and aromatic terpenes. Oftentimes, cannabis extraction producers attempt to create a final product that’s indicative of the source material. In other cases, individual phytocannabinoids like CBD are extracted, isolated, and used to make phytocannabinoid specific products.

The following three methods are generally considered some of the most common methods of cannabinoid extraction:

- Ethanol extraction. Considered one of the lowest cost and most efficient methods of extraction, ethanol extraction lets producers turn large amounts of plant material into a potent cannabis oil . This is done largely by soaking the cannabis in either hot, cold, or room temperature ethanol to extract the plant’s phytocannabinoid content. Once complete, the resulting solution is refined to remove residual solvent. The difference in temperature alters how much of the plant’s phytocannabinoids and terpenes will remain in the final product. It should be noted that the hot alcohol extraction method relies on the Soxhlet extraction technique, which requires a special extractor to complete.

- Carbon dioxide extraction. This non-toxic method utilizes carbon dioxide (CO2) as the separating agent. Because CO2 can easily fluctuate between its gaseous and liquid states, there are two different ways to use it for extraction: supercritical fluid extraction and subcritical fluid extraction.In supercritical fluid extraction, CO2 is heated and pressurized to a point where it exhibits gas and liquid properties. While in this state, it passes over ground plant material, dissolving trichomes, terpenes, cannabinoids, and other desired compounds into a liquid. That solution is then collected, cooled and processed into the final product. Subcritical extraction, however, uses lower temperatures and less pressure to achieve similar results. Since no heat is used in the process, more terpenes and cannabinoids make it to the final product. Though it takes longer and yields a smaller quantity, subcritical extraction is easier on the plant material.Both CO2 extraction methods require specialized equipment to do it safely, efficiently, and reliably. Since the CO2 naturally evaporates from the final product, it makes this method among the cleanest and safest for consumption.

- Butane extraction. Butane hash oil (BHO) or other extracts liked “shatter,” “crumble,” “wax,” or “budder” are all results of the butane extraction process. Used to create both THC-dominant and CBD-dominant concentrate products, butane extracts and separates the psychoactive properties of cannabis into an oily or waxy substance. Not unlike the CO2 extraction method, butane is passed over plant material to dissolve terpenes, cannabinoids, and other compounds. The butane is then removed from the resulting mixture with heat.

Why extracting terpenes with traditional methods is so difficult

For all their advantages, these common extraction methods have one major drawback: terpenes are often destroyed in the process. While CO2 extraction is less likely to destroy terpenes, the harsher butane and ethanol processes greatly diminish what can be extracted from the plant.

This compounds a process that’s already challenging enough to preserve the terpenes in the first place. As a short-chain hydrocarbon, terpenes begin to evaporate the moment cannabis is harvested. Though previously considered to be more trouble to salvage than they’re worth for growers to preserve, cultivators are now considering terpene preservation more carefully, as more emerges about how terpenes influence the cannabis consumption experience. Since terpenes are what contribute to each cultivar’s unique aroma and effects, their loss can be substantial and diminish the consumption experience.

Furthermore, monoterpenes are even more difficult to obtain since they boil off the plant at much lower temperatures than phytocannabinoids. The immediately noticeable cannabis scent in a grow room is the telltale sign of those very terpenes evaporating.

Since terpenes are so fragile, how you choose to extract them from your plant matters immensely. Ethanol extraction, for example, provides a greatly reduced yield of terpenes because of how harsh alcohol is on them. Other solvent-based extraction methods also run the risk of simply contaminating the terpenes, making the entire process moot if you’re interested in capturing these valuable compounds. It’s no wonder cannabis derived terpenes are worth tens of thousands of dollars, and proper preservation can quite literally add $1 million or more of revenue to your harvest.

Emerging cannabis extraction technologies

Though the following methods are not the most predominant ways of cannabis extraction, they are some of the more up-and-coming ways that some providers are producing these valuable products. You may have already heard of some of these methods from certain brands or companies, but still have a way to go before they’re considered major advancements in the cannabis industry.

1. Automation

While not exclusively an extraction technology, automation will continue to influence the cannabis industry. Artificial intelligence and advanced technologies hold the potential to bring numerous benefits to the cannabis companies at all steps of the product’s journey to the consumer. It could play a major role in cannabis extraction as the very machines that facilitate that extraction will be able to handle the process with significantly reduced need for human input. This will bring operating costs down and improve efficiency, accuracy, and output over time, though the initial costs will likely be too prohibitive for all but the largest operations.

2. Hydrodynamic extraction

If temperature and pressure conditions play important roles in traditional cannabis extraction methods, hydrodynamic extraction adds sound waves to the mix. Touted as one of the best ways to obtain full spectrum extract from cannabis flower, hydrodynamic extraction works by freezing the plant material and then using sound waves and moving water to draw out the phytocannabinoids and terpenes. The lower temperatures ensure that fewer terpenes boil off and that phytocannabinoids are preserved.

What results is a slurry that contains these compounds, as well as lipids and other materials. That mixture is then separated with a centrifuge before further distillation in a low temperature vacuum. The substance is then made into the final extract.

3. Ultrasound extraction

Where some extraction methods rely on heat and pressure to extract valuable terpenes and cannabinoids from plant material, some companies now utilize ultrasound assisted extraction. Seen as an enhancement to existing ethanol extraction methods, ultrasound extraction uses specialized equipment to emit sound waves at key points in the solvent. Those sound waves create tiny bubbles that heat and pressurize the immediate area as they burst. In those conditions, the very cells within the plant material begin to break down. During that time, the plant’s natural oils are more easily dissolved. This is seen as an improvement to regular ethanol extraction, since those oils are typically left behind in that process. What results from ultrasound extraction is a more potent product.

How Cryo Cure differs from other cannabinoid and terpene extraction technologies

Cryo Cure is seen first and foremost as a cannabis drying and curing technology – after all, our patent-pending process made its mark by cutting down drying time to as little as 13 hours. However, cannabis extractions from our product are vastly more potent and flavorful as well.

As written about in this guide, terpenes have a very short window for extraction. Through our live resinextraction process, our machines stabilize phytocannabinoids early in the drying and curing stage. This means that the compounds don’t have the opportunity to boil off or degrade before they’re extracted, resulting in a richer, higher-quality cannabis extract ready to use in concentrates, edibles, and more.

While you’re drying and curing flower with Cryo Cure, our machines recapture terpenes by capturing and cooling a vapor containing those terpenes and monoterpenes into an ice bank within the unit. Once complete, the ice is melted and the terpene-rich water that results is extracted and separated in a centrifuge. Through this method, our machines can recover 95% of the terpenes that traditional curing methods lose to evaporation. With this kind of collection easily going for $50 to $100 per milliliter, it’s an immediate revenue source that doesn’t diminish your flower.

In addition to those processes, our Cryo Cure machines come with an exclusive terpene extraction setting that allows you to collect up to 95% of the terpenes before phytocannabinoids are ever extracted. While more traditional extraction methods tend to harm one or the other, our machines make it so you can take advantage of both compounds from your plant.

Extraction tech continues to grow

It should go without saying that the cannabis industry will see major advancements in terpene extraction technology as more is learned about these compounds and consumer demand continues to grow. And while most of today’s methods require highly specialized equipment and attention to detail, Cyo Cure’s patent-pending machines make it easier than ever to get the most out of your cannabis. Whether you’re preparing a harvest just for extraction or want to recoup revenue that would otherwise quite literally disappear into thin air, Cryo Cure can help.