by Cryo Cure | Jun 21, 2023 | The Cryo Cure Experience, Updates

After the successful debut of its highly-anticipated CC-Micro freeze-drying machine for home and craft growers, Cryo Cure is proud to share that it’s partnering with extraction equipment manufacturer Holland Green Science to produce more units and distribute them on an international scale. The cannabis extraction equipment provider, based in the Netherlands with a North American headquarters in Chicago, will manufacture Cryo Cure’s CC-Micro machine, designed for home and craft growers to bring Cryo Cure technology to smaller harvests.

Why did Holland Green Science and Cryo Cure partner?

Cryo Cure is the company behind Live Resin Flower, which balances the flavorful and potent experience for which live resin extracts are known without affecting smokable flower’s integrity. Cryo Cure machines skip the hang drying phase and produce ready-to-smoke product in as little as 11 hours. Unlike standard freeze dryers, Cryo Cure machines dial in the right ratio of time, temperature, and pressure to preserve flower at the height of freshness. This stabilizes terpene profiles and cannabinoid levels while ensuring the flower is easy for consumers to break apart and use.

Michael Urosev, co-founder and CEO of Holland Green Science, described Cryo Cure as “a real innovator and risk taker” in the cannabis industry.

“I want to partner with companies that disrupt markets and challenge the established norms that we have in the cannabis industry, and Cryo Cure is… blazing a whole new territory in our market,” said Urosev. “The leaders of Cryo Cure think outside the box and have created an entirely new product category as a result. Simply put, Cryo Cure is synonymous with quality, freeze-dried flower.”

Tracee McAfee, CEO of Cryo Cure, said Holland Green Science’s global reach, deep cannabis knowledge, and commitment to product quality make them an ideal partner for the company.

“Holland Green Science is not only known for meeting international standards for safety and compliance, which is essential in our industry, but they are a truly global company with an established presence in cannabis markets around the world,” said McAfee. “Their international reach and careful diligence to quality make them a perfect partner to expand our reach to home growers and craft growers in the U.S., Europe, South America, and more territories.”

The move to the CC-Micro

Since its founding in 2018, Cryo Cure has manufactured large freeze drying units best suited for commercial grows. With the launch of the CC-Micro in May 2023, the company expanded its reach to home, hobbyist, and craft growers, successfully distilling Cryo Cure’s patented technology into a footprint less than three feet wide. The initial run of CC-Micro machines was met with great enthusiasm, selling out within weeks of launch.

“It’s been my goal to bring Cryo Cure to home growers and craft growers since our earliest days, and it took years of research and development to adapt our process to a smaller size at an affordable price,” McAfee said. “I am delighted to see that there’s so much demand, that we can pursue global reach with a world-class manufacturing and distribution partner.”

“Even with Cryo Cure’s success on a larger scale, Tracee and Greg [Baughman, Cryo Cure president and Head of Cultivation] never forgot about the home grower and the craft grower,” Urosev added. “Both us at Holland Green Science and Cryo Cure want large companies and the regular guy down the block alike to process cannabis safely and effectively. With the CC-Micro, Cryo Cure is one step closer to its goal of bringing their technology to cannabis enthusiasts everywhere.”

About the CC-Micro cannabis freeze drying at home unit

The CC-Micro holds approximately 1 to 2 wet pounds of cannabis, depending on the cultivar. Each machine is pre-programmed with Cryo Cure’s patented “recipe” for drying and curing flower, as well as recipes to make hash. The dry cycle time lasts around 11 to 16 hours. Machines come with 5-tray configurations, with 9-tray configurations available. Outside of cannabis, the CC-Micro can be used to freeze-dry fruits, vegetables, and other products.

How to pre-order the CC Micro

Cryo Cure is accepting pre-orders for the CC-Micro. The machines are available to ship throughout North America, South America, Europe, and select countries in Africa and Asia. Visit the CC Micro page to learn more about the machine and fill out the pre-order form.

by Tracee McAfee | Oct 24, 2022 | Live Resin Flower, The Cryo Cure Experience, Updates

This content was updated to reflect the product name change to Live Cured Flower.

When it comes to smokable flower, quality is king. And for the best quality available, there’s nothing like Live Cured Flower.

At Cryo Cure, we have perfected and patented a process for producing fresh from the farm live resin cannabis flower unlike anything else in the U.S. and global cannabis market. Our unique process consistently delivers top-shelf quality every time. What makes this “Live Cured Flower” stand out from the crowd? Read on to find out.

What is Cryo Cure’s Live Cured Flower?

Cryo Cure’s Live Cured Flower is driving a brand-new category of smokable flower. This flower is preserved in as fresh a state as possible. While freezing flower to extract live resin isn’t a new concept, creating a smokable flower from the same technology is an emerging category, driven by Cryo Cure’s globally-patented methodology. Simply put: You can’t get much closer to the “fresh from the farm” feeling as you can with Live Cured Flower.

Where did the term Live Cured Flower come from?

The term “Live Cured Flower” combines the flavorful and potent experience you’d get from extract sourced from frozen flower while still enjoying the experience of smokable flower. That’s because Cryo Cure’s process goes beyond simple freeze drying to retain all those cannabinoids and terpenes live resin is famous for preserving.

Our patented process stabilizes all those compounds, yes, but it also retains the integrity of the smokable flower by locking in the perfect moisture content level – not too dry as to make it impossible to handle, and not too damp as to inhibit mold or mildew growth. Our smokable flower features the best of both of these worlds; it’s a flower of impeccable quality that preserves flavor and potency at the height of freshness.

How does Live Cured Flower work?

The main goal with Live Cured Flower is to preserve natural resin at its peak, maximizing flower quality and supporting an unparalleled consumer experience. Fresh preservation of cannabis helps to keep trichomes fully intact, maintaining the resin inside as close to its “live” state as possible.

Freezing cannabis directly following harvest eliminates the traditional process of hang drying, a weeks-long period in which cannabinoids and terpenes are exposed to the elements and begin to degrade. Cryo Cure reduces the drying time to 11 to 14 hours. And unlike other freeze drying methods that leave the flower dry as dust and deprived of its terpenes, Cryo Cure never needs to be rehydrated.

The result is Live Cured Flower with higher cannabinoid and terpene content. You can tell the difference just by looking at it: Live Cured Flower is vibrant in color, with no shrinkage, and smells just like a fresh growing plant, with none of the “grassy” smell or taste.

What is Cryo Cure’s Live Cured Flower used for?

Some of the most common applications for this flower include:

Smoking or vaping

You can treat our Live Cured Flower just like other top shelf flower. Not only does Cryo Cure’s have undeniable shelf appeal, but consumers notice the difference from the get-go. For rollers or people who vape, Live Cured Flower offers a discerning experience unlike anything else they’ve tried before.

Live Cured Flower contains rich terpene profiles for an unforgettably flavorful and aromatic session. Labs have found elusive monoterpenes in this flower, terpenes that normally evaporate off at room temperatures. One example, Delta-3 Carene, has been studied for its impact on bone health.

Along with monoterpenes, Live Cured Flower preserves cannabinoids in their acidic state before they’re converted into active cannabinoids. High levels of THC-A, CBD-A, and CBG-A, just to name a few, can be found in Live Cured Flower.

And most importantly, Live Cured Flower makes for a smooth smoking experience. It breaks apart nicely, making it ideal for packing a bowl or rolling a joint with ease. There’s no grinder necessary, either – the flower is soft enough to come apart with your hands without losing its integrity. Just be sure to store it properly, away from heat and light. There’s no need to freeze, refrigerate, or “rehydrate” Live Cured Flower – all it needs is a cool, dark storage spot in a sealed container.

Extraction

Live Cured Flower can be used to produce live resin extract without the use of chilling material columns or using cold solvent. This saves processors the costs of using expensive chillers while seeing production increases of up to 500%. The starting material never leaves the cold chain process until the point of extraction leaving the resulting crude to have the same properties of fresh frozen extract.

Extractors can create all sorts of concentrates from Live Cured Flower, not just live resin. Cryo Cured flower is regularly used to create diamonds and other types of concentrates, used in edibles, to create tinctures, and much more.

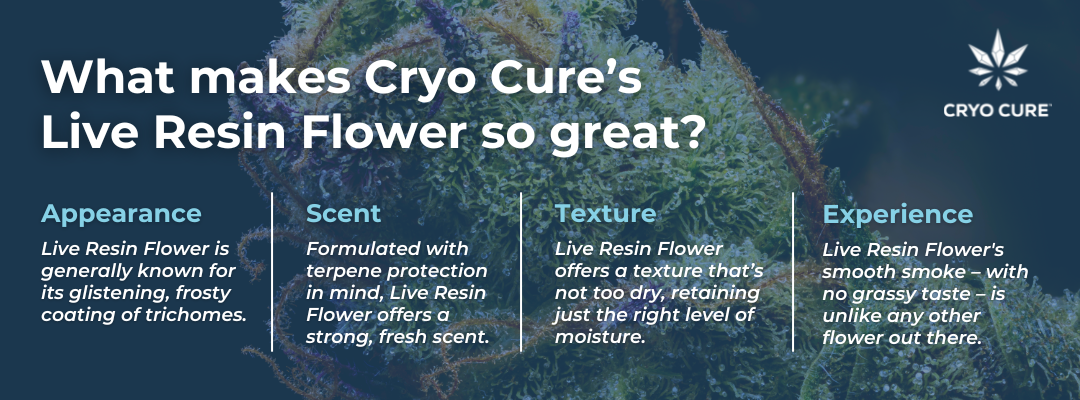

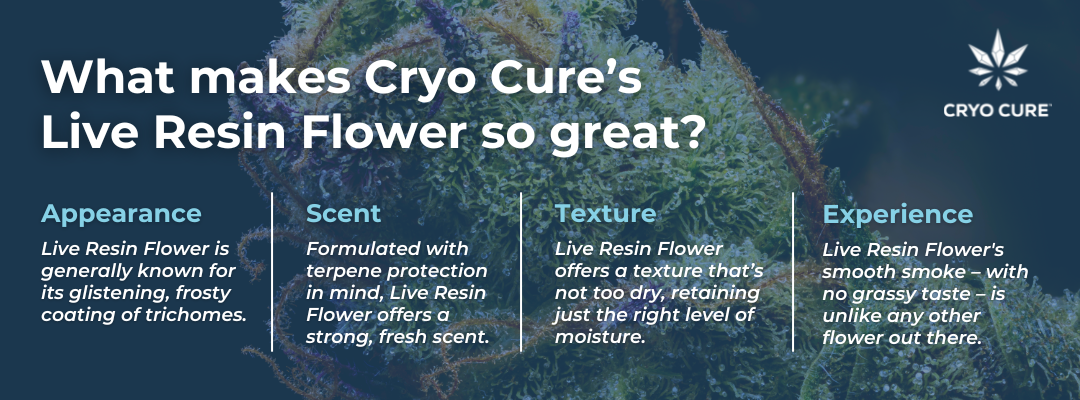

Characteristics of Cryo Cure’s Live Cured Flower

Cryo Cure produces the first and only Live Cured Flower, known for its bright appearance, potent aroma, and robust flavors. Characteristics of Live Cured Flower include:

- Appearance: Color, size, and shape are typically the easiest ways to differentiate premium cannabis flower like Live Cured Flower from standard options. Live Cured Flower is generally known for its glistening, frosty coating of trichomes, too.

- Scent: Our Live Cured Flower offers a strong, fresh scent that’s much more alluring than traditionally cured cannabis, which can lose some of its smell as terpenes evaporate off during the hang-drying process. Formulated with terpene protection in mind, the Cryo Cure process preserves significant terpene content, the driver behind the smell and flavor of any cultivar.

- Texture: Cryo Cure’s Live Cured Flower offers a texture that’s not too dry, retaining just the right level of moisture to make it easy to work with without encouraging molds and mildews. While traditional cannabis flower may range in consistency, premium cannabis flower will generally be sticky and spongy but still dry enough to produce a “snap” when broken apart.

- Consumption experience: The smooth smoke – with no grassy taste – is unlike any other flower out there. But it’s not just how it feels, but the consumption experience itself. By stabilizing the curing process, Cryo Cure’s Live Cured Flower offers a rush of therapeutic cannabinoids and a bounty of terpenes that are full of flavor. The process even preserves rare and fragile terpenes not found in other flower.

Live Cured Flower from Cryo Cure

Cryo Cure is proud to have perfected our patented process to manufacture premium Live Cured Flower. In addition to cutting the time and hassle of drying and curing, Cryo Cure can yield the same results every time, making it reliable and suitable for a standardized process and consistency. A quality grow can reach new heights when it undergoes the Cryo Cure process.

From the smell to the taste to the feel, Cryo Cure is shaping not just a new tier of smokable flower, but new categories that expand what we know and appreciate about cannabis. Schedule a consultation to learn more about how we can help you harvest vibrant and aromatic Live Cured Flower.

by Tracee McAfee | Feb 2, 2022 | In the Press, Updates

The revolutionary process behind Cryo Cured cannabis and hemp flower is now officially patented!

Cryo Cure leadership has been awarded Patent #11,243,028, which covers the unique system and methods of cryo-curing responsible for our flower. The patent takes effect on Feb. 8th, 2022.

The Cryo Cure process and machinery utilizes lyophilization, also known as freeze drying, to achieve results. However, what makes Cryo Cure unique is the proprietary “recipe” inside the machines that allow the cultivator to successfully maintain optimal moisture and terpene content for smokable cannabis.

Cryo Cure’s technologies and methodologies allow cultivators to skip the hanging phase of drying, cutting the traditional processing time from weeks to hours. The resulting product looks just like it does on the plant, with no flower shrinkage and trichomes and terpenes wholly intact. The flavor profile is preserved at the height of freshness. The process has earned Cryo Cured flower a reputation for “fresh from the farm” appeal, with unforgettable and unmatchable visuals, smell, and taste.

This vibrant flower stands head and shoulders above other freeze-dried cannabis due to this now-patented process. Unlike other freeze-dried cannabis, no rehydration is necessary, smells and flavors aren’t lost to the freezes drying process, and flower retains its integrity and does not crumble in a customer’s hands. The issuance of this patent is confirmation that the Cryo Cure team has developed a system that revolutionizes how cultivators dry and cure their plants.

To learn more about how Cryo Cure works, explore our resources: