The Processor’s Guide to Live Rosin

Live rosin has taken the cannabis world by storm, appealing to enthusiasts who appreciate its purity and the high levels of terpenes it retains. This solventless extract can be produced through a relatively straightforward process that results in a potent, flavorful, and high quality product that doesn’t need any further remediation.

For processors, live rosin represents a premium product that can complement their other offerings, showcasing their artisanal capabilities when it comes to producing top notch extracts. This guide explains how processors can make live rosin, why it’s becoming so popular among consumers, and what’s needed (like Cryo Cured flower!) to create a live rosin that truly stands out from the crowd.

What is live rosin?

Live rosin is a solventless extract that is made by subjecting bubble hash sourced from fresh frozen cannabis to heat and pressure. This is typically done using a rosin press, which features two plates that can be heated and pressed together to squeeze resin from the bubble hash, resulting in live rosin.

Live rosin is typically highly potent and retains a significant amount of the plant’s terpenes, making it a top choice for connoisseurs who want an extract as close to the natural strain’s compound profile as possible.

Live resin vs. rosin vs. live rosin

Live rosin is commonly confused with live resin or rosin, but those are distinct types of cannabis products. Rosin is extracted from hash made from dried cannabis flower, kief, or trim. Live rosin is extracted from hash made from fresh frozen cannabis flower. Like live rosin, live resin is also extracted from fresh frozen cannabis flower, but live resin is made using solvent-based extraction methods, usually employing light hydrocarbons like propane or butane as the solvents.

The rising popularity of live rosin

Live concentrates — a category that includes both live rosin and live resin — are a small yet growing category in the cannabis market. In the U.S., concentrates represent roughly 9.5% of the legal cannabis market. Live concentrates make up a third of that segment, more than 3% of the total U.S. cannabis industry’s value. By that measurement, and given that the U.S. cannabis industry was estimated to be worth $10.8 billion in 2021, live concentrates were worth roughly $338 million in 2021.

But how much of that value can be attributed to live rosin? Rosins, which include live and otherwise, represented just 7% of the concentrates market. Compared to live concentrates as a whole, the sales numbers for rosin are a portion of this growing category. And within that, live rosin is a portion of that portion.

However, looking at sales data doesn’t tell the whole story. Live rosin consumers are loyal customers who prefer solventless extracts for their flavor due to preserved terpenes and high THC levels. They also want an extract that closely mimics that natural state of the cultivar from which it was produced. While live rosin may not be as famous as flower or edibles, cannabis connoisseurs and industry leaders alike appreciate this concentrate for its quality and potency.

Why is live rosin so popular?

Live rosin is a premium product, and as such it tends to fetch a higher price than other concentrates. In fact, rosins are typically the highest priced concentrates on the market, usually priced between $50 and $120 per gram. And while this premium extract doesn’t command the lion’s share of the concentrates market, it does demonstrate the quality a processor offers by creating that platinum level product offering for scrutinizing consumers.

Here’s a look at some of the benefits that drive live rosin’s premium price point and exceptional quality.

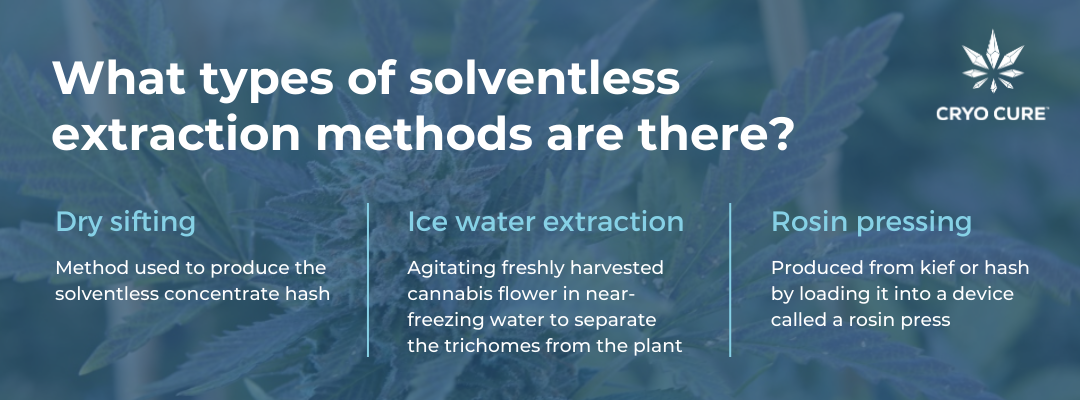

- Solventless production: The unique factor that sets live rosin apart, even from other live concentrates that come from frozen cannabis flower, is the solventless production method used to make it. Fresh frozen flower is made into bubble hash by way of ice water extraction, a method that requires no solvents and preserves compounds by using near-freezing water to separate trichomes from the plant. Then, dried bubble hash is loaded into a rosin press, which uses heat and pressure to squeeze the viscous live rosin from the bubble hash — no solvents required. No solvents means no remediation to remove residual solvents, and it means no left behind solvents that sneak by under state-mandated testing thresholds. The result is a smoother consumption experience.

- Superior terpene content: Live concentrates in general offer superior terpene content because they start with fresh frozen flower. Unlike conventionally dried and cured flower, fresh frozen flower is preserved as close to its just-harvested state as possible, leaving valuable terpenes intact and preventing them from degrading. Starting with fresh frozen flower, coupled with the solventless ice water extraction process, means live rosin is jam-packed with flavorful and aromatic terpenes that enhance the consumption experience and boost the extract’s therapeutic properties.

- Potent cannabinoid profile: Similarly, using fresh frozen flower and a solventless extraction process serves to preserve cannabinoids like THC and CBD. The end result is a more potent live extract. For discerning consumers who want the broadest possible spectrum of cannabinoids, live rosin can’t be beat.

- Similarity to natural plant: Many other extracts undergo significant winterization and remediation following extraction, but live rosin doesn’t require these steps. As a result, the compound profile found in live rosin is similar in the proportions of cannabinoids and terpenes to the source cultivar in its natural form. This gives consumers an unparalleled experience that keeps them as close to the plant as possible, while still enjoying the benefits of consuming a concentrated extract.

- Versatility: Live rosin can be used in a number of ways. While dabbing or vaporizing live rosin is the most common, it can also be used alongside cannabis flower or even in the production of edibles, as you’ll learn more about below.

These benefits are why live rosin fetches such a high price. While not every consumer will pay a premium for it, there are plenty that understand live rosin’s benefits.

How to make live rosin

Live rosin can be made in the following easy (but important) steps, which makes it a great choice for processors who don’t want to add another complex process to their operations. Best of all, the equipment required to make live rosin is relatively simple.

1. Start with fresh frozen cannabis flower

The most essential step in the production of live rosin is to source fresh frozen cannabis flower that’s been properly preserved — otherwise, you’re not making live rosin at all. With a process like Cryo Cure, freshly harvested cannabis flower is dried and cured in an average of 11 to 14 hours, depending on the cultivar. Our technology, which creates Live Resin Flower, preserves flower at the peak of freshness, saving the maximum amount of cannabinoids and terpenes for the whole cannabis processing journey. Using fresh frozen cannabis flower like this ensures you start with the greatest possible amount of desirable compounds that the refined palates of live rosin consumers demand.

2. Layer micron bags in ascending order

In the production of bubble hash, the first step in producing live rosin from fresh frozen flower, a series of fine mesh bags are used to sift the trichomes that will be separated from the plant material during the wash. Before you begin the wash, layer your bags in ascending order so that they become increasingly fine. Typically, processors use a range of bags from 25 microns to 220 microns.

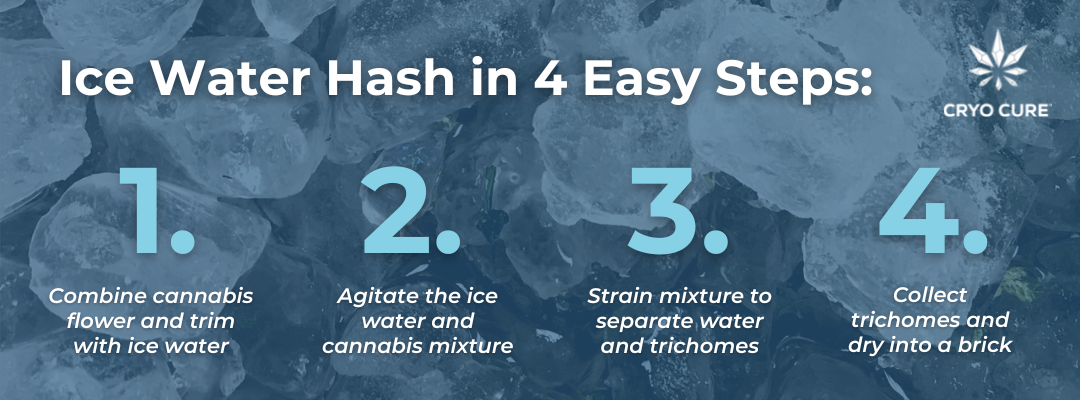

3. Wash or agitate cannabis flower

The next step is to wash or agitate your fresh frozen cannabis flower in near-freezing water. This can be done manually in large buckets, though many processors today rely on wash machines. Wash machines can create a vortex that is optimal for separating trichomes from the plant material without damaging them, keeping the resin glands intact with the cannabinoids and terpenes inside.

4. Strain trichomes through micron bags

Once the wash is complete, the mixture is strained through the micron bags layered together in the second step. Let the trichome and water mixture flow through the bags, ensuring you’ve captured every bit of solution from the wash before proceeding to the next step.

5. Remove micron bags and scrape trichomes

Remove each bag one by one, starting with the least fine mesh. As you pull each bag out, the water will flow out of it. In each bag, there may be some trichomes left behind; scrape them out and store them separately.

Note that the finest “full melt bubble hash” has no residual plant material in it at all. This potent bubble hash is typically found between 72 and 120 microns, though this can vary depending on the source cultivar and the size of the trichomes you’re working with. Typically, processors will keep the full melt separate from the other extract, as it’s a particularly high quality extract.

After you’ve collected all the extracted trichomes, freeze them into bricks of bubble hash by placing them in a freeze dryer for up to 24 hours.

6. Press bubble hash into live rosin

Once the bubble hash has finished freeze drying, place it in your rosin press to press it into live rosin. Ideally, you should press your bubble hash at temperatures between 160°F and 210°F. This will be warm enough to squeeze your live rosin from the hash while preserving valuable terpenes. Collect the resulting live rosin and prepare it for storage.

3 live rosin applications

Live rosin is a versatile extract that gives processors the opportunity to sell it for a variety of applications. Whether you’re a manufacturer at a vertically integrated organization with its own retail element or you’re pitching a dispensary on why they should choose you as a live rosin supplier, keep these three use cases in mind.

- Dabbing or vaping: The most common use cases for live rosin are dabbing or vaporizing. Unlike live resin, live rosin doesn’t contain any residual solvents. This results in a smoother dabbing or vaping experience for the consumer, with all the terpene-packed flavor that live concentrates offer.

- Enhancing flower: Sometimes called “twaxing,” live rosin can be added to smokable flower to enhance the experience and add more potency. Whether you paint a bit of live rosin on the outside of your joint or stick a bit of flower to it before packing a bowl, it’s a great option for taking your next smoke sesh to the next level.

- Cooking or baking edibles: Live rosin can be used to create infused butter or oil for the creation of edibles. There is a bit of a learning curve to this method, but it can end up making some unique tasting products. First, live rosin must be properly decarboxylated so the cannabinoids are activated for oral ingestion. Doing so without destroying cannabinoids and terpenes takes some knowledge. Additionally, live rosin is very flavorful, so it won’t mix well with every type of edible product; but if you combine it with the right ingredients, you may find some exciting new flavors.

Can live rosin use any fresh flower?

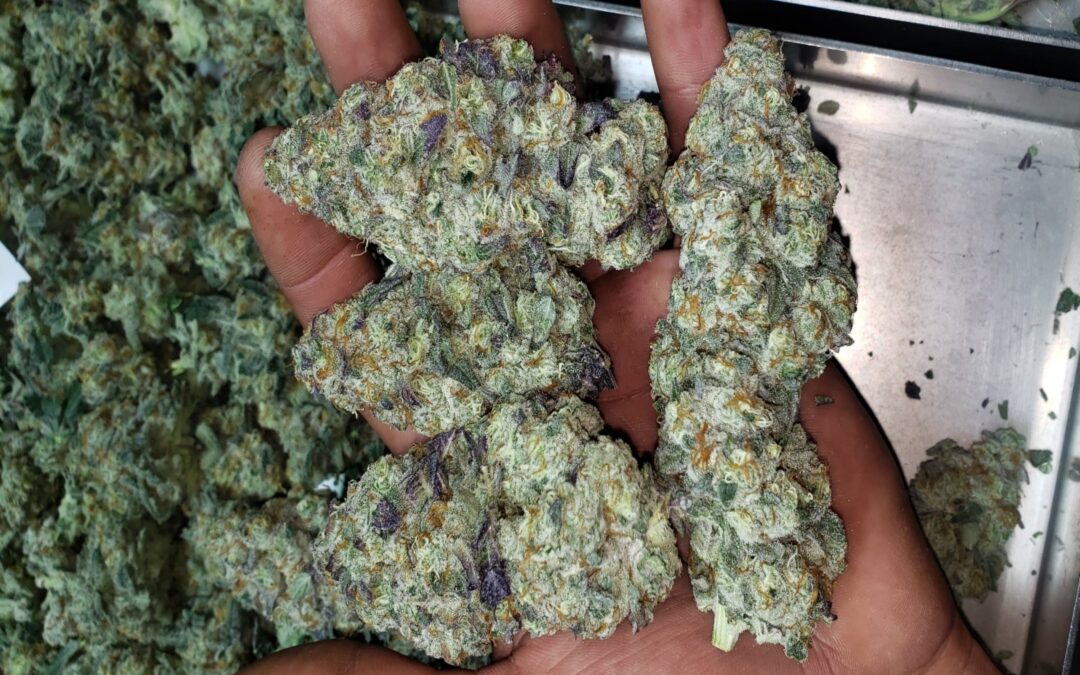

Fresh frozen flower is required for the production of live rosin, but if you want the best quality not any fresh frozen flower will do. To get the most out of your flower, it’s important that it preserve cannabinoids and terpenes at the peak of freshness, and that’s where Cryo Cure’s Live Resin Flower comes in.

Using Cryo Cure’s patented process, freshly harvested flower can be dried and cured in anywhere from 11 to 14 hours, sealing in the perfect water activity levels and balancing out water activity to optimal levels. The result is what we call Live Resin Flower, an unmatched premium cannabis flower that retains the body, appearance, aroma, flavor, and potency of a bud freshly plucked from a mature cannabis plant.

In addition to providing a superior smoking experience, Live Resin Flower is also ideal for making live rosin. Not only is its shelf-life extended beyond that of conventionally dried and cured flower, allowing processors to store it without fear of degradation, it also gets the process started on the right foot, with the most possible cannabinoids and terpenes.

When making live rosin, you’re producing a cannabis product intended for the most experienced, knowledgeable consumers. So, in order to gain a competitive advantage, you need the highest quality live rosin on the market. To produce a superior, premium live rosin means starting with a superior, premium flower — Cryo Cure can ensure you have just that.

Live rosin delivers for the most discerning consumers

Live rosin is a premium cannabis product that’s becoming increasingly popular among consumers who prioritize quality, purity, and authenticity. That’s because live rosin blends its solventless extract process with fresh frozen cannabis, resulting in exceptionally potent terpene and cannabinoid profiles that replicate the natural state of the plant. But to meet these consumers’ expectations and create a top quality product, processors need to start with the best possible fresh frozen flower. For the absolute best live rosin, processors should start with Cryo Cure’s Live Resin Flower.